Part of a continuing series on restoring this radio:

Part 1 – History and First Looks

Part 2 – Tool Prep

Part 3 – Capacitor Can Rebuild

Part 4 – Capacitors and Socket Replacement

Part 5 – Finished!

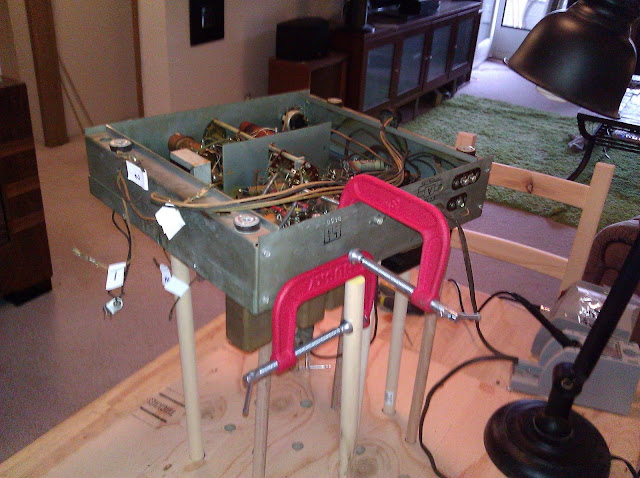

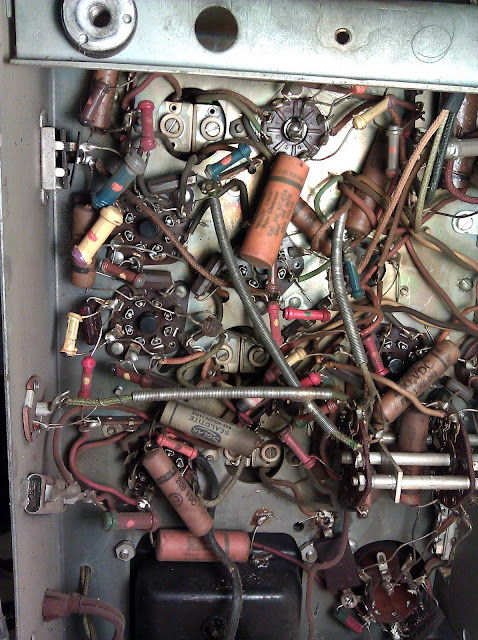

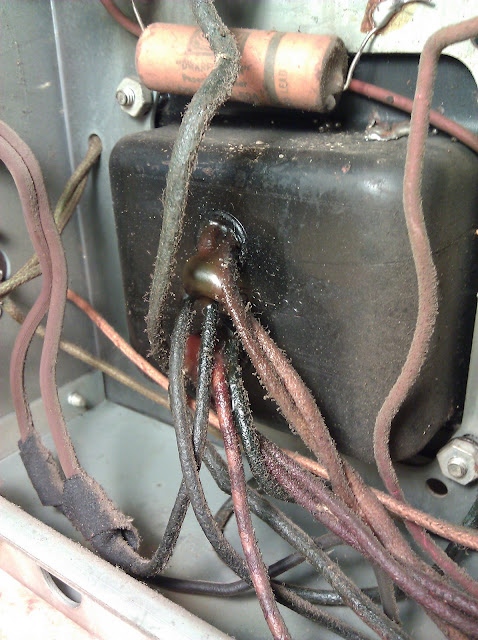

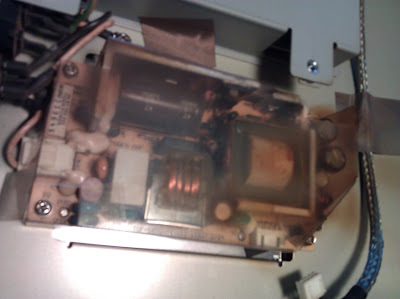

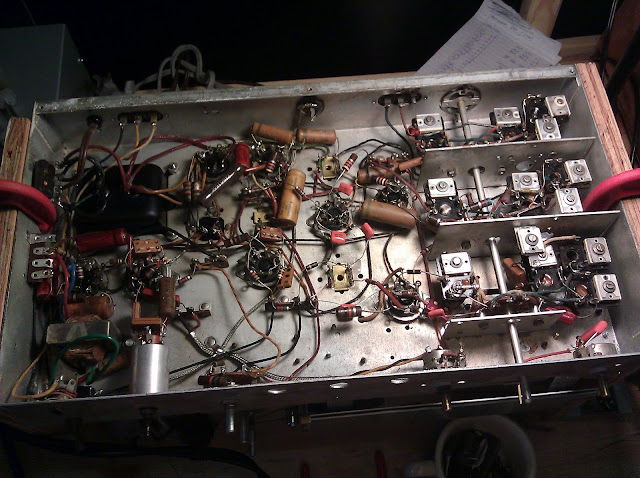

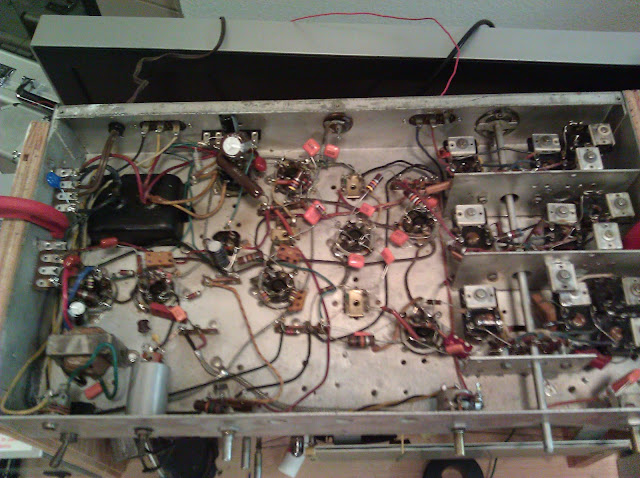

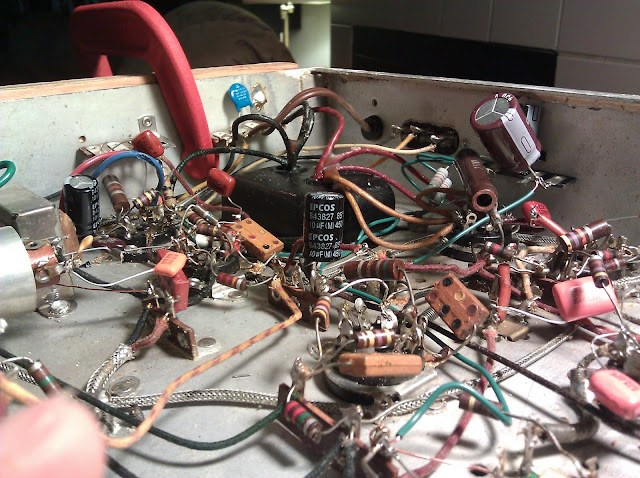

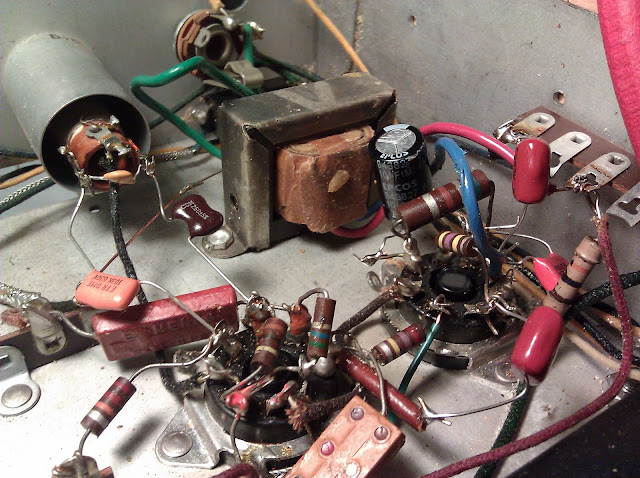

I’m continuing to work on my 1942 GE LF-116 radio. In part 1, I showed a few photos of it and talked briefly about the history and showed some photos of the different views of the cabinet and chassis. This radio has protrusions on all sides of the chassis – screws, metal seams, switches, an RCA jack, antenna and speaker terminals, and controls in the front – there’s no viable location to do my normal mounting trick of a C-Clamp and a small piece of plywood to form a stand, suspending the radio from each end. I searched the antique radio forums for a few ideas and came up with a simple one – a thick wood base with holes drilled and dowels inserted. The holes are drilled such that the dowel will land on an empty spot on the top side of the chassis, supporting it without damaging any components while it’s being serviced upside down.

I started with a pair of 2′ x 2′ x 3/4″ plywood sheets as the base, with them glued together it makes a 1.5″ thick mounting platform – should provide plenty of stability. This GE radio’s chassis is quite heavy.

I then clamped it to the edge of my coffee table and went to get lunch while it set.

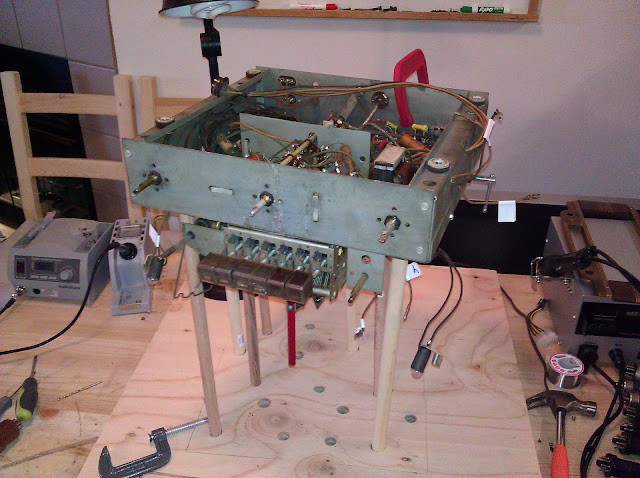

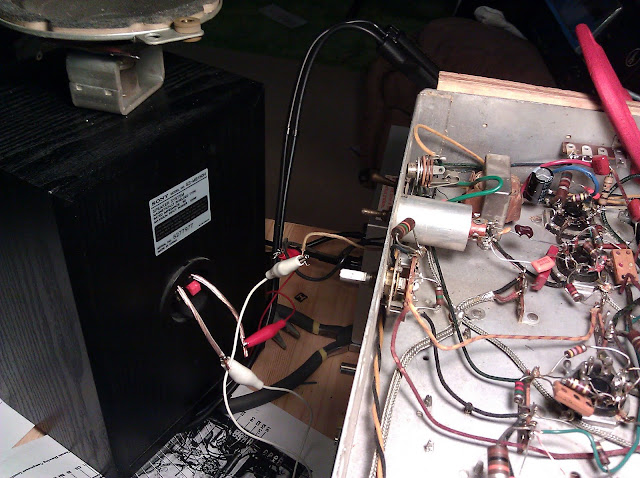

The dowels are cut to size, 16″ each. I used a mix of 3/4″ oak (stiffer) and 5/8″ depending on where the dowel would touch the radio – if there were tight clearances. Faintly visible under the dowels are the guide marks for where to drill for this particular chassis.

I randomly drilled extra holes after the original marked ones were done just on expectation of using this with other chassis. I used an oversized base for the same reason – I might work on some bigger ones eventually. It came out okay:

And all mounted up:

Now the real work can begin. It’s not perfect, but it’ll do – the 5/8″ dowels and dowel holes fit together like I want them to – slightly snugly – but either the 3/4″ dowels or my 3/4″ bits are slightly off-sized as they fit only loosely. With 8 segments supporting it (including a few in between components where it couldn’t slip out) and the c-clamp arrangement in the back fixing its horizontal position, I’m satisfied it’s sturdy enough for light repair work as I’m doing. This won’t be a permanent solution, though. Steve Strong from the OKC antique radio club makes articulated chassis holders that mount to the existing chassis bolts and rotate 360° to provide perfect control. I’ll be picking one of those up in a few weeks, but sadly after I’m done with this.

Steve, e-mail linked above, is selling these for $57.50 + shipping and they’re custom made to order.

Antique Radios in “Babylon 5”

In Season 2, Episode 7 of television program “Babylon 5” (1994-1998), you can see a few antique radios in the space station’s Earth History Exhibit.

With the help of some other radio hobbyists, I’ve identified the interesting ones. On the top shelf left to right, the wooden Tombstone radio is an unknown Wilcox-Gay model from around 1934; next is a Zenith 5G500 portable radio with Wave Magnet antenna, the Red square is an Emerson model 560, and finally the blue peaking out of the frame on the right of the top shelf is a 1960s GE radio in the C430A family. None of those are particularly special radios now, although they are nice and interesting, and in the ’90s they were probably easier to find for cheaper.

Share this: