My friend recently purchased a 1991 Mazda Miata from its original owner, in immaculate condition and with incredibly low miles. Except for one issue: the Air Bag light on the instrument cluster was indicating a trouble code. The number of blinks of the light indicates the fault and the light was flashing 10 times, meaning the System Down Fuse had opened. This fault keeps the air bag system from working resulting in reduced safety in the event of a crash, so it’s important to take care of. Used modules can run around $100, with new computer modules starting over $200.

As these cars are getting to be over 20 years old, these module issues have been known for a while and the cause identified: faulty electrolytic capacitors cause the thermal fuse to blow, disabling the system. Capacitors are at the root of pretty much every electrical problem, it seems. We decided to try repairing the module after some research that showed it’s a common problem with a fairly straightforward fix.

This rest of this article demonstrates modifications to your car’s occupant restraint system that are not approved by the manufacturer and if executed improperly could result in your serious injury or death from the air bag failing to deploy, or deploying unexpectedly.

The repair involves sensitive components which can be damaged by improper handling, furthering the risk of an unexpected failure. This information is provided only for experienced automotive and electronics technicians as an academic exercise, and KF7LZE is not liable for any consequences arising from following or failing to follow these instruction.

The module is a little blue package that lives up near the steering wheel on the 1990-1993 Miatas. This part wasn’t used in the entire range of the first generation’s production due to revisions that happened along the way. It was also used in similar years of the Ford Taurus, the Mazda RX-7, and there may also be other Ford and Mazda cars using the same air bag module which have similar faults.

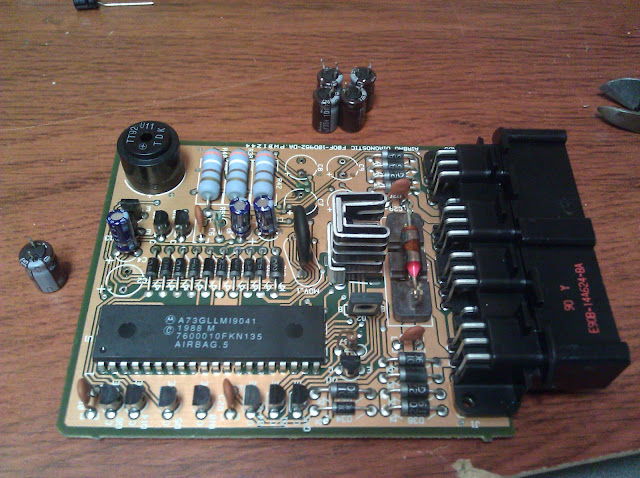

We unmounted the board from its housing, then got down to business by removing the bad capacitors:

If one capacitor of a set is bad, it’s very likely the rest of them will be soon. This board uses 5 x 100uF 35V electrolytic capacitors and 3 x 10uF 35V capacitors, all rated at 105°C, along with an assortment of other components that aren’t subject to failure the same way. When replacing, you can use any voltage rating as long as it’s 35V or higher. (I’ve linked to 50V variants above, which will last even longer in this circuit.)

The System Down Fuse is the long, red-tipped object parallel with the connector on the right side of the photo. A quick continuity check revealed yes, it was in fact open.

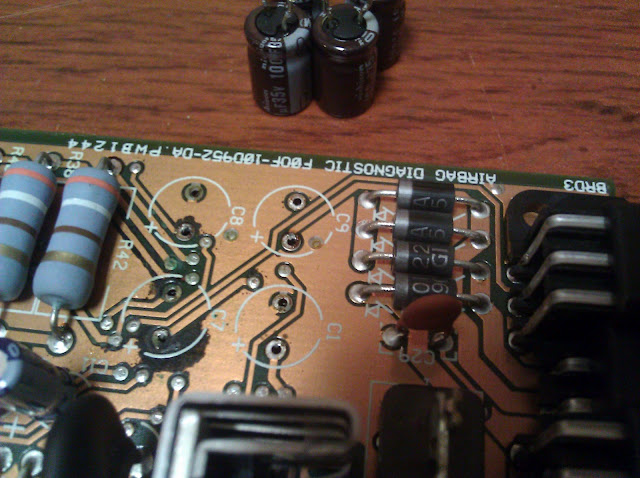

After removing the bad caps, from the black spots around the bottom of C7 (center-left in the photo, lower right of R42) you can clearly see the electrolytic fluid had leaked from the bottom of the cans and etched the board a little, but the damage wasn’t that bad. Rubbing alcohol took off some of the residue, but it’s more cosmetic than operational damage and since this board lives inside of a plastic housing itself located inside the steering column nobody is ever going to see it. Replacing the capacitors was very straightforward: de-solder pads, pull old caps, insert leads, and re-solder pads. My Hakko de-soldering tool makes this job very easy, but with any tool it’s important not to overheat the joint or the traces could de-laminate from the board and that usually means the part is destroyed.

Here’s the thermal fuse on its housing. The fuse is the center component, and wrapped around it is a flexible trace completing a circuit between the two center pins. I’m not sure what purpose it serves, but it makes a complete circuit so it’s important to save it. It might be a current sensing winding around the fuse to send a signal when the inflators are triggered, but that’s just speculation based on its placement. Reader Craig Mason wrote on describing the flexible wrapping’s purpose: it’s the heater designed to cause the thermal fuse to blow. When the system detects a fault, Q2 in the circuit switches on and triggers the SCR U2 to conduct current through the heater wrap. At 141°C, the fuse opens and the system is taken offline.

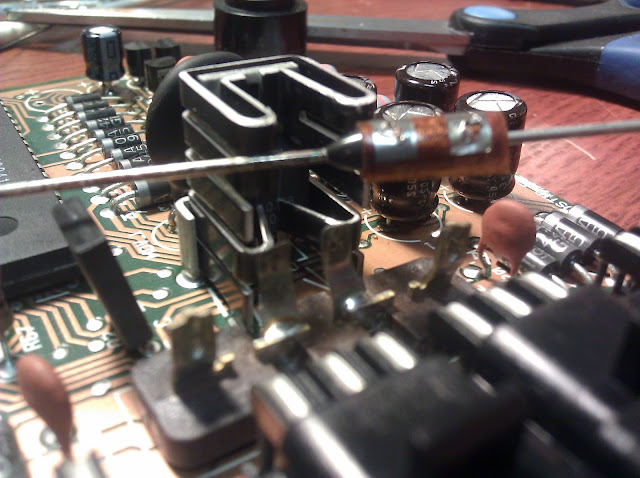

Be very careful – the foil contacts are very, very fragile and difficult to solder.

As you can see, the foil came off the terminal when it was removed. Not good, but not the end of the world either – it’s fixable.

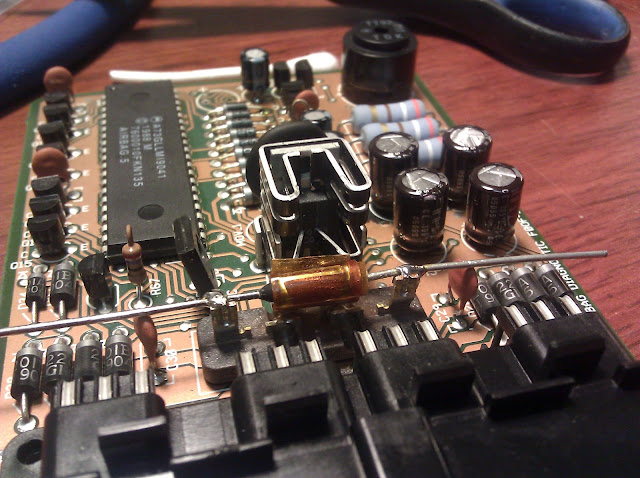

Here’s another view of the board, showing the replaced capacitors mounted up.

Repairing the foil trace was a delicate process. The original connection was a very small contact area, and when it snapped off it removed a bit of foil. There was a thin layer of resin-like insulation over the remaining portions of the foil wrap that needed to be scraped off to expose the bare metal underneath. We first tinned the metal contacts on the fuse mount body, then heated the foil contact pad from the back while applying pressure to force the foil pad into the metal terminal. Once the solder starts to flow, remove the heat but continue to apply pressure – rolling the iron back so it wasn’t applying heat, but could apply pressure as the joint cooled. This took quite a few tries – looking at it wrong the first few times caused it to break off, taking a little more foil off each time. It finally made a good, solid connection and we wrapped it back around the new thermal fuse.

There was a lot of controversy about the thermal fuse replacement on various Miata forums while we did pre-op research. Most commenters who have attempted this repair in the past have been held up on a lack of information about the part number for the thermal component. I can only assume the flexible heater destroyed the part numbers on the fuse in most cases. For a safety-critical part such as this one, it’s important it have the right ratings or it could fail to allow the air bag to ignite in a crash or cause an electrical fire after a crash. Several people suggest to replace it with various alternate standard resistors and fuses, but I don’t recommend this shortcut.

…replacing it with a standard fuse, metal film resistor, or whatever would circumvent its primary function. Thus, the bottom line is that replacing it with anything but an identical item would risk air bag deployment at the improper time…

After unrolling the film from the old thermal fuse, there were still some very faint, but readable, part numbers listed – very surprising. It’s a Motorola part, which goes well with the Motorola controller chip onboard. Part number 4283A.

The bag the old fuse is resting on gives away the next step a bit. When looked up in the NTE Cross Reference, 4283A brings up a modern part number replacement. It’s an NTE8139: 141°C, 15A thermal cut-off! And it’s available in modern production. No need to worry about replacing it with a different part and changing the operation of a safety-critical circuit when an identical component will do!

This bears repeating: the air bag system down fuse in a first-generation Mazda Miata is an NTE8139 It’s about $5 on Amazon.

The new fuse gets installed and soldered into place, wrapped again in the original flexible trace that covered it before. It’s very important to remember this is a heat-sensitive device, and you’re soldering to it. We only applied heat for about 10 seconds max at a time, and it was just barely enough to get it to take the solder. The first 10 seconds were a cold joint with the solder holding it in place, the second 10 seconds reflowed the cold joint to be a proper joint to ensure the fuse wouldn’t open up while it was being installed. If you overheat the thermal fuse, you’ll destroy it.

Finally, clip the extra-long leads down to size, reinstall the board in the housing, the housing in the car, and fire it up: The light came on briefly at the start like it should, then blinked off. NO CODES! The air bag system passed all self-diagnostics. We think it’s ready to protect him in the unlikely event of a collision, but there’s of course no way of testing that short of crashing the car. The controller thinks the system is fine, and the parts were replaced with identical new replacements, but full system functionality testing is impossible.

The total cost of the project was about $15 worth of parts, and a couple hours standing over a soldering iron.

This is a fairly straightforward rework job, but you must take special care to not overheat the thermal fuse when installing the replacement or it will fail. I’d recommend using an a solder clip or other heat-sink between the terminal and the fuse body, and it really helped to have two pairs of hands working on this to hold the fuse in place while the other person soldered. If you don’t have a friend who can hold it in place, definitely use a soldering assist device.

Parts:

NTE8139 Thermal Fuse ~ $5

100uF 50V Electrolytic Capacitors ~ $5

10uF 50V Electrolytic Capacitors ~ $5

And remember, use this information at your own risk. You should not attempt this repair yourself, and KF7LZE is not responsible for the consequences of failing to follow these warnings. Any fixes you do based on these instructions is as your own risk!

I wanted to thank you for your detailed instructions and your diligence in getting the correct replacement for the “impossible” and “irreplaceable ” fuse that had so many tossing in the towel. I am ordering the parts (thanks for part #) and will replace the electrolytics and the fuse. And anything else that isn’t up to spec. I’ve got a pretty good soldering rig, and ESR Meter that also tests Transistors, so ‘ll get it done properly. I get 10 blinks on my 91 Miata, so I thinking the hardest part is getting my mitts on the modules. I am quite motivated to repair the airbag module, being recently involved in an accident that totaled my car (Honda CRV) and every air bag deployed. I hate to think what would have happened were I driving the Miata.

I was surprised to see that you repair and work with old radios. You have a lot of experience. I have recovered an old Fender Bassman Amp, and a Super Reverb. All the repair pros say first thing you do is replace the electrolytics. I’d like to get a hold of an older radio or TV. Some of those looked really cool. Especially those old tubes!

Thanks and Happy Thanksgiving!

I just took apart the thermal fuse unit on my 1990 Miata airbag diagnostic module, and instead of foil, it has a coil of wire wrapped around the fuse, and the fuse is a Microtemp 4415A, a 15A fuse with an operating temperature of 216C . A similar fuse is part number NTE8213.

So there are at least two versions of this fuse system. The coil of wire (I assume it’s nichrome) is attached to much smaller tabs than in your pictures.

I had this repair done to my 90 Mata and it only lasted two days. Then the airbag light quit working at all. No light at key on or start up. Any ideas on why? In Virginia it will not pass inspection if air bag light does not work.

When I had airbag problems, I made a schematic of the computer board. I’ll look at it and see what might kill the light. The connectors themselves have a built in switch that turns on the light if they are disconnected from the board. If you unplug them and start the car and get no light, then I think it must be the bulb or wiring.

The condenser fluid is corrosive ? The tracks are dirty or disappear?

On my module, several traces along the 4 capacitors are quite affected.

Yes, the electrolyte is very corrosive.

Is there supposed to be continuity between the left and right leads that are soldered to the orange flexible trace?

Sorry, Seth – I don’t have any more info than what’s on this page already. I’d probably recommend finding a new module in your case if it is damaged or has something other than capacitors wrong. Remember, all modifications like this are exclusively at your own risk.

Thanks for the reply back. I went ahead and buttoned it back up and installed it back. No airbag light as of yet! Here’s to hoping my pathetic soldering will last after the first speed bump I hit.

I’m not clear on whether you understand the purpose of the fuse. It is intentionally blown when the diagnostic module detects that one of the crash sensors has failed to prevent an accidental deployment if another one fails. Here’s how it works. It only takes a signal from one crash sensor to activate the heating coil around fuse but it takes two or more to activate the inflation signal which goes thru the fuse. Since it takes a while for the fuse to blow, it is ok when the very fast inflation signal goes thru. However, if only one crash sensor is activated, say by a sensor fault, there is no inflation signal, the fuse is blown after some delay and the airbag is effectively deactivated preventing an accidental deployment later. So, yes there must be continuity through the heating coil for it to work.

15 ohms. This is a heater strip. When there is a circuit fault, Q2 switches on and triggers the SCR U2 to conduct high current to the heater. The heater then hits 141c and blows the thermal fuse. Shorted caps and intermittent functions will trigger Q2 to conduct current. The orange tape is a polyimide film commonly known as Kapton. It is a high temp film. Be careful as the heater strip generally doesn’t solder well, if at all. I used silver bearing epoxy used as die attach adhesive for microelectronics manufacturing.

Pingback: September Update | KF7LZE's Blog

JWK,

Great blog post!

I’m currently doing this repair myself (and certainly understand the warning in RED letters above). How would you suggest changing the thermal fuse after your experience? Can I heat the trace and have the foil separate? I can tell this is going to get messed up, or at least be very difficult. If you had to do another, how would you approach it–same way as in your article?

Also, is the thermal fuse crimped on at its connections?? I’ve put a lot of heat on the thermal fuse connections, it won’t come free of the post.

Any feedback would be greatly appreciated! Thanks!

RBR

That’s an interesting question. Honestly, I think there’s just going to be some risk to it. It’s a thin metal film on a plastic backing soldered to tiny contacts. I’d probably do the same thing except even more slowly, possibly with a magnifying glass. I’d be worried about heating the trace ruining it before it would actually free itself but you might have different luck. Be careful. At your own risk. Etc.

fwiw, i wanted to track down the nichicon al electrolytic capacitors. here is what i found:

35V 100uF

nichicon p/n: UPB1V101MPD

mouser p/n: 647 – UPB1V101MPD

p/n on capacitor: B1111

35V 10uF

nichicon p/n: UVR1V100MDD1TD

mouser p/n: 647 – UVR1V100MDD1TD

p/n on capacitor: B1302

Outstanding article. Thanks so much for this. Pardon if I missed it, but is there a part number for the capacitors?

There is not specifically; they’re a commodity component so any with the correct rating in uF and Volts will work just fine.

1. When you unplug the connectors from the diagnostic module, the instrument light is grounded within the connector itself which is intended to warn you that it is disconnected. You can remove a thin piece of metal that lies between the two sets of pins to turn off the light.

2. The wire wrapped around the thermal fuse is used by the module as a disconnect trigger when it detects that any of the three D sensors is shorted to ground and the S sensor is not. (If it were you are crashing.). This would allow a subsequent problem with the S sensor to fire the bag. To prevent this situation, the module puts a current through the wrapped wire which heats the thermal fuse until it blows. This causes the 10 blink error code which tells you your air bag has self disconnected. The fuse does not blow due to current going thru it which only happens when it fires the bag. Don’t install a new thermal fuse without the trigger.

Does anyone know the procedure to remove the front shroud and plastic bezel from the instrument cluster to apply masking tape directly over the air bag light that remains on?

Following the above comments, I was able to determine that the two plugs from the wire harness that plug into the control module, have a definite fit. The plugs are not interchangable into the module.

My fix on the control module did not solve the air bag light problem. Leaving the the module in place would provide for a (5 count) flashing on the airbag dash light. A bit frustrating so I decided to remove the control module and leave the wiring harnes disconnectd. This would also incude the back up battery source. This would result in the air bag instrument light being on all the time.

The question than became as to if there would be an option to disconnet or disable the air bag instrument light. After checking with a few repair sources, come to find that this light is not a conventional light bulb but an LED light that is part of a circuit board. Sources also indicated that attempting to disconnect or disable the light might compromise the circuit board that would impact all warning lights within the dash cluster. Best not to go there.

Next choice would be to put a piece of tape on the plastic bezel covering the dash cluster to mask the light. This helps but is not the total answer. This approach will not completely mask the light.

Total answer would be to remove the dash board cluster assembly and then try to remove the plastic bezel which covers the dash board itself. Next would be to apply tape over the air bag light. The caution here is that these plastic bezels, due to age, can be quite brittle. Removing them can be a task that may create the bezel to fracture. That said, best bet may be to live with the problem and create a new mind set that when the air bag light is on, it is saying the system is now activated…which it is not.

Figured the information might be worth sharing.

CT

Hi JWK… Hope you had a great Thanksgiving… I’m on temporary hold for additional repairs to the air bag computer module awaiting any information forthcoming from your contact with the “car’s owner”. In short recap, I need to know if the plug in leads going into the module are interchangeable. In your above photo, it appears that the plug in housings are duplicates to each other. If this is the case, how might one identify which lead (black or white plug) goes into which socket. If they are reversed, what would be the prognosis?

I intend to remove the module and check all my connections (capacitors) and fuse to see if it is blown. (I purchased an extra thermal fuse when I placed the original order) What’s weird about this issue is that after my original repairs, the system was functional (no airbag light comimg on) after 4-6 seconds of start up. Problem occured about a week later.

Might you see if you could “nudge” your friend for more information. If your friend would want to call me, that’s OK too.

On the audio front, looks like I have acquaired a McIntosh MX113 Stereo Preamp/

Tuner from an old friend of mine. This preamp is same as McIntosh C-26 except it incorporates a tuner. Next is to find a Mac amp to go with it, This would make for two Mac systems.

Thanks again for you help!!

CT

Would look forward to meeting with you. Hopefully in the near future. I will be interested on your “take” to the system(s) I have. Some people think I should sell tickets.

The fix on the Miata went well per my previous comments; however, a week after the repairs were done and all was working well, air bag light started flashing again. Sill looks like it might be the computer module. I purchased an extra fuse but would like any additional imformation on the input connections.

Thanks!! CT

Chuck, I just helped out with the electronics. I’ll have to ask the car’s owner about the physical connections, we’ll see if he gets back to me in a few days. By the way, I’ll shoot you a message next time I’m down in Tacoma/Gig Harbor, I’d love to take you up on that offer to check out your system.

Question on reconnecting plug in leads from wire harness to the diagnostic computer module. There is a black plug-in lead and a white (cream colored) plug-in lead. Looking at the 2 inputs on the module it appears either leads could be plugged into the wrong input. I don’t see any key slot that would prohibit an inproper connection. I could be wrong with this assumption but figured I would check first. Can you verify proper connections?

RC

Just wanted to give all and update of the module repair on the 1991 Mazda Miata. First let me say that the tutorial on this fix was concise and constructive. I will note, for those of you are “first time” players with this kind of fix, it can be very challenging. My parts finall come in so work could commence.

First was to disconnect the battery and attempt to remove the front driver seat. I had thought one might move the seat up on the rails and if far enought forward could be removed from the rails. Not so. You have to unscrew the rail bolts to accomplish this. Can be difficult since cars this age have some of their bolts that are really frozen in place.

Next was to remove the module. I would say the biggest challenge here was the tight working quarters and a wire harness that doesn’t like to be manipulated. The two plugs into the module and the plug to the battery back up module were easy to disconnect.

Next came the work on the airbag module itself. The pictures incuded with the tutorial can be a bit misleading due to the very nice large pictures provided. You will note, after removing the module and cover plate protecting the ciicuit board, that this circuit board is quite small and loaded with electronics. Refurbishment will require a lot of precise handing.

Part of my challenge was R & R of all capacitors and fuse. Unfortuntely, I only had a small 30W soldering iron ( small soldering point ) for this job. Issue was trying to get enought heat to melt the solder so capacitor legs could be removed. Ended up having to refurbish some of the electrical fittings since pullng the capacitors out of their soldered base was putting too much of a strain on the fittings. Solder would just not heat up enougy quickly to make for ease of removal. I don’t have a “de-soldering” gun but this would be a great investment to have. It took an number of hours and patience to replace all requested capacitors along with refurbishment of a number of fittings.

The replacement of the fuse was rather straight forward. It is very important to follow the tutorial or whatever instructions are provided with your fuse purchase to insure proper working installation.

Installation of the refurbished module can also be a challenge. Remember all the twisting you had to do to the wire harness to make the removal. You will have to do it all over again.

Also make sure you remember what plug goes into what socket. The module takes two plugs. I made note upon the original removal which went where. While I can’t confirm my next comment, it appears the size of key slots for these plugs would provide for either plug from the harness. I didn’t check to confirm; however, it looked like the would.

Now everything gets buttoned down and it’s test time. I was mentally prepard to put myself on a scale of six (ten being the highest) This was due to circuit board issues I had with an improper soldering iron.

Re-hooked the battery, put key in the ignition, and…. air bag light came on…for around 6 seconds, and went off!!!! How great is that?

For those of you willing to tackle this project, my advice is “take your time, go slow, and double check your work. If everything works after refurbishment, GREAT! If it doesn’t, you can assure yourself it wasn’t because you didn’t double check you work. As with most electrical project, you normally will only get one chance.

Thanks again for all the help. Just felt it might be worth sharing this adventure.

CT

I have placed the order with VETCO so we will see what they send. The only capacitor affected by the higher voltage is the 10uF which appears to be the smaller of the two.

Also was able to do a brief check for locaion of the module under the stearing wheel. It does not appear that this module is bolted or attached to any structure under the dash. It appears to be held in place with just the plug ins from the two wiring harness connections. Do you know if these connections can merely be pulled out from the module base or are there any retaining clips that come into play. Connections of this nature can be sometimes a “bear” to remove. Sure are a lot of harness wires used in these two connectors.

It might. Depends on how much bigger, really.

Would this create a mounting progblem to the circuit board?

Definitely. You can always to higher in voltage rating, just never lower. Higher voltage will be a little physically bigger, though.

Just heard back from VETCO after placing my order and they advised the the required capacitors we have need for have a 50V rating as opposedto a 35V. Would it be safe to proceed with this alternative.

Gotta ya!! Just heard back from VETCO that they have all necessary parts needed for this repair. Apparently they are in the process of having to update their web site on capacitors to include what has not been listed. I will be getting in an order shortly and will keep in contact.

CT

I am checking again with VETCO on the 10uF 35V Electrolytic Capacitor (105C). The issue appears that capacitor they show on their order sheet has a 24V rating. Nothing is shown on their order sheet for the same capacitor withthe 35V rating. They have said they have stock on all the specifics I need but I’m having a challenge confirming that they have EXACTLY what I need. I should hear something tomorrow. I have also emailed Mouser a request for product information.

Glad to hear you are into “old technology” audio”. Do you ever get down to the Gig Harbor area? Don’t know if you are famaliar with Bozak. Won’t get into history detail here but suffice to say, if you have never heard of Bozak (not Bose), you would be in for a shocking suprise. With my Mac’s running, they drive a total of 12 drivers per side or a total of 24 drivers.

Some say the listening experience is better than live concert as you alway have the best seat in the house.

Enought said… You’re welcome to visit and take a listen.

Let me know if you would like the Antique Radio Publication.

Chuck T

Chuck, I’m just a guy like you posting a personal experience here. Postings from the owner of the blog ( and the author of the great article ) appear with the initials jwk at the right margin. Ron

Hi Ron… Thank for the prompt reply. I have contacted VETCO and am about ready to place my parts order. The only issue I am dealing with is that their web site shows they have only the 10uF Electrolytic Capacitor in a 25v format and not a 35v format. Your tutorial indicates a need for 35v format. Is this critical? I contacted them via email to confirm what was needed and they indicated all items were in stock. They also said the only way to move ahead on the project would be to place an order. I have the order to be placed and have noted concerns as to making sure they ship the right 10uF 35v capacitor. Also that all capacitors should be rated at 105C.

Thought I mignt check with on any issue that would be created if they only have the 25v and not the 35v. I just don’t want to receive an item that was not needed or ordered.

Also, I was able to find a local repair shop that will remove the the module under the steering wheel for $40.00. I think this would be a cost effective approach considering front seat removal and tight quarters to unconnect and remove the unit. That way I can concentrate on the fix.

I think were moving ahead.

One more note. I have a reference book on old antique radios. It is called Collector’s Guide to Antique Radios – Fourth Edition. by Marty & Sue Bunis. Don’t know if you would be interested. I have no need for it.

Last note. With interests seen in “old technology” electronics, do audio components fall into your interest catagory. This would include products: i.e. McIntosh, Bozak, DBX, Micro Acoustics, Audio Control, Pickering, Thorens, etc?

Chuck

Chuck, you could also purchase components from Mouser (www.mouser.com). They might also have the NTE thermal fuse. The voltage needs to be the same, or higher, as the parts originally rated on the board. Please make sure to observe the large red warnings I’ve called out in this entry for obvious reasons. This is a more advanced project than many I’ve posted here due to the nature of the air bag controller’s purpose in your car.

I am certainly interested in classic audio components. I have a nice old Marantz 400m receiver on my bench waiting on some parts, and a tall pile of vintage speakers and receivers. Nothing like the sound from an old hi-fi!

Your article on the repair of the airbag module sensor is excellent. I am quite handy with electrical repair of this nature and intend to repair the defective module I have (1991 Miata.

A few questions: How difficult is the module removal. With the removal of the module, will this disable the airbag system (including flashing light) but still allow the car to be operated? Is disconnecting the battery necessary prior to removal? I don’t want to create any electrical issues with other components of the vehicle.

Suggestion for source to secure the necessary capacitors and thermal fuse?

Might you be able to send me an email direct on these questions Certainly OK to post for others to review.

Thanks!!

Chuck Thompson

Gig Harbor, Wa

Hi Chuck,

My father lived in Gig Harbor for 17 years in retirement. I envy you.

The thread above should answer most of your questions. Remove the seat and then the removal of the computer becomes much easier ( but not easy ). Without the computer the airbag is disabled but the light remains illuminated steady. It does not affect any other system.

Disconnecting the battery prior to doing anything on an airbag is always the proper procedure.

Hope this helps.

Ron Olsen

Well, I removed the diagnostic computer, with several results. First, with very little pressure on the computer, a few of the plastic clips on the brackets the computer fits into broke. The car had spent almost all of its life in the extreme dry heat of Texas, so that wouldn’t be considered unusual. When I opened it, the housing that the thermal fuse sits in had come loose from the motherboard. It looked like the soldering of the four pins had been cold. The fuse and housing was free to move about within the computer as the car went over bumps and around corners. This accounts ( I believe ) for the various codes I would see. The thermal fuse was open and I had significantly more black electrolytic fluid leakage from the capacitors than shown in the pictures above.

Because of the age of the computer and the numerous problems, I have elected not to attempt to repair it. Investigating new computers, they cost $466 plus tax at my local Mazda dealer, and about $360 on other websites, if you can find them. My solution ( for me, I am not recommending this for anyone else ), is to remove the air bag. The car is a Sunday go to lunch in the summer vehicle, and there is no air bag on the passenger side anyway.

With the computer removed, the air bag light stays illuminated continuously. I’ll remove the air bag ( plenty of help on other internet sites – disconnect the battery first ) and then remove the bulb for the airbag light.

To jwk; – Thanks again for this great article. Nothing anywhere like it is available, that I have found, and I have had the airbag problem for two years. Please consider submitting it to the miata.net for inclusion in their garage section.

Ron

Is it expensive.

Thanks jwk. I understand your red warnings thoroughly! Because of my work/vacation schedule it might be a while before I get back to you with the results – but I will.

The chip would require a new module, it’s an ASIC that is likely not available individually and has some programming to it. Make sure to weigh my large, red-lettered warning thoroughly before proceeding with any repairs, of course!

I’m going to replace all the capacitors and the thermal fuse ( with your help ). If, after that, I still have airbag light issues, is the chip definitely the next suspect? If it is, is the chip something I can replace myself without frying the board ( which I might do anyway ). Or, at that point, should I just go out and look for a replacement diagnostic computer?

Ron Olsen

P.S. For others reading this, the diagnostic computer’s Part Number is NA01-67-7F0A. As of today, it’s not available at Moss Motors ot Planet Miata.

Thanks, Ron! I’m the electronics guru, but I don’t actually own the Miata myself. We replaced all the capacitors, because the general rule is that if any are bad, all of them of the same age will be. In this case, the bad capacitors had visibly leaked out the bottom and discolored the board around them. Sometimes, this leakage happens out the top and results in a bit of a crust on the top of the capacitors; other times it is not enough to leak but does cause the top to bulge outward. The wikipedia article on Capacitor Plague http://en.wikipedia.org/wiki/Capacitor_plague has many photos of failed capacitors, although the rest of the information is specific to components from a particular time period and application that doesn’t apply to the Miata air bag diagnostic computer.

If I had to guess, I’d say your capacitors aren’t failed as completely as these were yet; the chip may be throwing off random codes but if it’s primarily 10, it does indicate the thermal fuse is likely bad as well.

Great Instructions! Thanks for sharing. My 91 airbag warning blinks most of the time, but sometimes not. The number of blinks varies, mostly 10, sometimes 7,5, etc. Sometimes I get the audio, mostly not. I don’t know how much Miata experience you have, but do you have any ideas?

My question is; You say to replace the bad capacitors. Did you do that, or just replace all 8? If you just replaced the bad capacitors, how can I tell they’re bad?

Thanks again for this wonderful article that will help hundreds ( if not more ) of us who are trying to keep these great old cars on the road.

Please consider sharing this with the miata.net for inclusion in their garage section.